Business News CMT WARNS RISING VLSFO QUALITY ISSUES CALLS FOR STRONGER MONITORING

페이지 정보

작성자 최고관리자 댓글 0건 조회 35회 작성일 25-09-11 11:00본문

CMT WARNS RISING VLSFO QUALITY ISSUES CALLS FOR STRONGER MONITORING

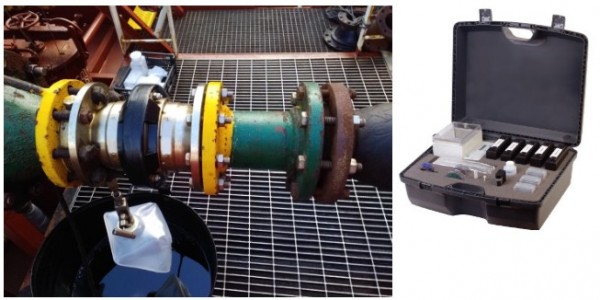

Taking a fuel sample onboard ship and using the CMT fuel test kit can determine if VLSFO is fit for purpose

Condition monitoring specialist CM Technologies (CMT) has warned that the recent spike in fuel quality problems at major bunkering hubs is creating fresh operational risks for shipowners and underlines the need for more rigorous real-time monitoring on board.

Reports from Bureau Veritas VeriFuel, VPS, FOBAS have indicated that very low sulphur fuel oil (VLSFO) supplied in Amsterdam-Rotterdam-Antwerp (ARA), Skagen and Piraeus contained higher than expected levels of catalytic fines, sediment and/or viscosity.

Independent data showed in the ARA region alone more than half of all VLSFO samples tested in 2Q 2025 were off-spec due to excessive sediment, up sharply from 43% in the first quarter. Skagen recorded 84% of samples testing off-spec, while in Piraeus one in eight VLSFO deliveries failed to meet specification.Global analyses also point to persistent problems in other hubs, with off-spec fuels reported in Houston and Antwerp and compliance concerns linked to poor blending and barge contamination.

One market analyst reported in January 2025 that more than 45% of the global VLSFO supply does not meet the RM380 grade ISO standards introduced in 2024.

“Bunkering with off-spec fuel continues to be a real issue,” says David Fuhlbrügge, Managing Director, CM Technologies. “The transition from traditional fuel oils to VLSFO has created ongoing problems for ship operators, with fuel quality issues becoming a persistent concern across major bunkering hubs since the introduction of the fuel more than ten years ago.”

Analysis points to persistent fuel issues that can be offset with easy, on-site testing capabilities that can quickly assess fuel quality before it enters the engine.

“Without robust monitoring, operators are exposing themselves to serious operational and financial risks,” Fuhlbrügge says. “Our role is to provide crews with precise and practical instruments that can flag issues in real time, preventing engine failures and costly delays.”

Catalytic fines in particular present an immediate threat to critical components, acting like microscopic sandpaper on injectors and pumps. Sediment, sludge and wax formation increase the risk of clogged filters and purifiers, while abnormally high viscosity disrupts combustion and raises fuel consumption. Inconsistent fuel quality can rapidly undermine even the most carefully planned maintenance schedules and compromise a vessel’s emissions performance.

CMT says wax formation when low viscosity VLSFO is stored in temperatures above 21 °C is particular problem.

CMT has built its reputation over more than three decades by providing test kits, sensors and laboratory services for monitoring and evaluating fuel quality. Portable tools for measuring cat fines, viscosity, density, acid number, wax and other insolubles are among the company’s most widely used devices. They are engineered for fast and reliable results on board, allowing engineers to act quickly when fuel samples do not meet expectations.

“Reliable data is the only defence against unexpected fuel behaviour,” Fuhlbrügge says. “Crews need immediate, accurate results they can trust, whether they are screening for cat fines, measuring viscosity or checking sediment levels. By identifying problems early, operators can take corrective action before fuel-related issues cause serious damage.”

The consequences of poor or non-existent monitoring extend beyond equipment wear.

Unplanned stoppages and repairs carry major commercial implications, from off-hire penalties to charter party disputes. With increasing pressure on shipowners to maintain high utilisation while cutting emissions, any disruption linked to fuel quality undermines both operational and environmental performance.

CM Technologies emphasised that monitoring should be viewed as an ongoing process rather than a one-time precaution. On-site analysis provides rapid initial screening, while laboratory services confirm results and enable long-term trend evaluation. By combining both approaches, operators can identify risks immediately while building a clear picture of fuel performance over time.

With reports pointing to continued instability in VLSFO supply and evidence of similar issues in other global hubs, CM Technologies believes the bunker industry should have a more effective governing body with a mandate to establish comprehensive regulatory control over bunker quality and compatibility.

Fuhlbrügge says: “VLSFO is a persistent problem for ship managers and charterers. Operators must know exactly what is going into their tanks. Effective monitoring onboard and at the bunkering port is the only way to protect machinery, safeguard operations and preserve reliability.

■ Contact: CMT https://cmtechnologies.de/en