Special Report Floating Offshore Wind Power Feasibility Project

페이지 정보

작성자 최고관리자 댓글 0건 조회 4,135회 작성일 20-04-14 15:08본문

1. Wind Power Summary

(1) Concept

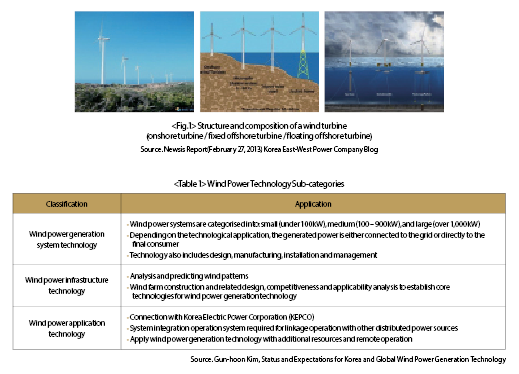

Wind power generation is the concept of converting wind-based kinetic energy into electric (or mechanical) energy. Generation technology refers to the wind power generation system, which supplies converted energy to the grid and the consumer.

Wind power technology is sub-categorised into wind power generation system technology, wind power infrastructure technology, and wind power application technology.

(2) Categorisation

There are two classes of wind turbines-onshore and offshore, with which categorisation depends on installation location. Offshore wind turbines, like onshore turbines, have a rotor and generator installed on top of a tower, which is held together with a substructure.

Offshore wind power is further sub-categorised into fixed – substructure is attached to the seabed – and floating – substructure is on-water.

- Depths under 20m: In shallow waters, gravity-based and monopole structures are widely used.

- Depths under 40m: Jacket-style foundations, such as tripods, are generally used. Jacket application is possible for large wind turbines over 5MW; however, potential stress on connection points must be duly considered during the design phase.

- Depths over 40m: In deeper waters, floating wind turbines are preferred over fixed turbines.

2. Floating Wind Power Generation Technology

(1) Necessity

Floating wind turbines are more environmentally friendly than onshore turbines. Furthermore, it is simpler to set up larger offshore wind farms. The seabed is also relatively flatter than dry land making for a lesser turbulence intensity and a consistent wind direction.

The further-out and deeper the sea gets, the wind gets stronger, which allows for usage of a greater area as a wind farm. If the seabed’s gradient is too steep, installation of fixed wind turbines becomes difficult, thus limiting installation to shallow waters.

Floating wind turbines are used in deeper waters to take advantage of stronger winds. Also, as floating turbines do not require fixation, the depth and condition of the seabed are not particularly important. This allows for application into new and previously inaccessible areas of the sea. However, high costs associated with greater distances to onshore grid connection and offshore construction compared to onshore construction must be considered.

(2) Composition technology

① turbine(generator)

A wind turbine is composed of a tower, blade(s), gearbox, and several other elements.

- Tower and Blade: The tower supports the wind generator, and the generator then converts wind energy into rotational energy.

- Hub system and Shaft: The hub system connects the pivot and blade(s) / The shaft delivers rotational energy from the blades to the gearbox or generator.

- Gearbox and Generator: The gearbox converts the pivot’s low revolutions to high revolutions. / The generator receives mechanical energy from the gearbox and converts it to electrical energy.

- Yawing system and Pitch system: The yawing system rotates the nacelle so that the blade is positioned with the wind. / The pitch system controls the blades relative to wind speeds.

- Control system and Monitoring system: The control system is set so that the wind turbine can be autonomously managed. / The monitoring system helps to make decisions either remotely or from on-land.

② Floating body and Mooring system

Floating offshore wind power systems require moorings to fix its towers. Currently, many types of floating-related concept prototypes are being tested, such as semi-submersibles, Tension Leg Platform(TLP), and spar-type systems.

The semi-submersible system relies on a catenary mooring floating buoys with multiple posts. The TLP system uses a tension mooring system for its floatation. And the SPAR system relies on a single support pillar for floatation.(Fig.4)

The mooring line helps keep the floating body within a specific area. It is primarily composed of a mooring line and anchoring.

- Mooring line: The floating body is fixed underwater to the mooring system. The mooring method varies depending on the upper structure and the water’s depth. The mooring line also varies – slack catenary, taut catenary or a tension leg mooring system – depending on the installation method and difficulty.

- Anchoring: The dynamic effects of the water’s depth and anchoring, condition of the seabed and interaction with the anchor, the applicability of new material, and high-quality monitoring solutions are all required. Drag embedded anchor systems are generally used for semi-submersible platforms; however, recently, suction systems are gradually being applied.

③ Grid connection

An offshore wind farm’s energy system is composed of wind turbines, an internal electrical grid(internal electrical cables), an offshore substation and an external electrical grid. Grid connection between the offshore wind farm and land varies considerably depending on the distance and water’s depth, but accounts for, on average, 15% of construction costs.

An offshore substation accumulates and relays electricity produced by the offshore wind turbines via the external grid to an onshore substation. The internal grid’s, distribution ready electric supply is delivered to the external grid where it is converted at the substation in preparation for delivery and connection to the onshore grid.

The transmission cable connecting the offshore substation with the onshore connection point transmits high voltage energy produced on the offshore wind farms to the land through the offshore substation.

3. Floating offshore wind power market conditions and outlook

(1) Global

① Wind power market conditions

Globally, 539, 583MW(as at December 2017) have been installed. In 2017 along, a total of 52,578MW worth of turbines were installed, up 3.94% from 2016.

② Offshore wind power market conditions

Global offshore wind power installations(as at December 2017) accounted for 3.5%(18,814MW) of total wind energy installations, with 4,331MW worth of new installations in 2017. Although compared to onshore wind installations, offshore installations are low, when only considering offshore installations year-on-year installations are increasing quickly.

The United Kingdom(U.K.) accounted for 34.4% of installations a 7,963MW. The U.K., Germany, Denmark, the Netherlands and Belgium accounted for 98% of installations in Europe and 77% of installations globally.

Outside Europe, China accounted for the most installations and excluding China; there are almost no existing projects.

③ Floating offshore wind power market condition and outlook

The seas surrounding Europe, Asia and the United States are all rich in wind; as a result, floating wind power generation projects are gradually being investigated. After the world’s first floating wind farm, Hywind Scotland was established in 2017. Since then, countries such as Portugal and France have begun looking into commercial projects to prove the feasibility of commercial floating wind farms.

From 2011 to 2014, floating wind power only accounted for 0.1% of the Carbon Trust’s offshore wind power investments. However, beginning in 2015, with the onset of large-scale projects, it was expected that floating wind power would account for 10% of investments by 2020. If Equinor’s industrial-sized farm, which can produce an excess of 100MW, goes according to plan, then it is expected to have installed a total of 237MW by 2020 and 13GW by 2030. From the 13GW, 4.5GW would be distributed to Asia, 6.5GW to Europe and 2GW to the U.S.

By 2030, as the competitiveness of offshore wind power improves, the construction rate of wind farms are expected to increase gradually. The Global Wind Energy Council(GWEC) estimates a total offshore wind power production volume of 120GW by 2030. And as floating offshore wind turbine costs fall, it is expected that they will make up for 10% of all installations by 2030.

(2) Korea

During 2H 2017, Korea’s domestic wind power installations totalled 1,139.91MW, with 97% of all installations being made onshore. The onshore installations consist of 86 farms and 560 turbines, which cumulatively produce 1,101MW.

During 2018, there was a total of 40 planned offshore wind farms which either planned or being constructed. Of those, eight were floating offshore wind farms. From the fixed offshore wind farms, Tamra Offshore Wind Farm, Korea’s first industrial offshore wind farm, which sits 1km off the Western coast of Jeju Island has a total installations capacity of 30MW and produces 85,000MWh annually.

The Seonam Offshore Wind Farm(fixed turbines) is approximately 10km off the West coast of Korea with a total capacity of 400MW. It is currently undergoing a three-step installation process.

- Stage 1(Feasibility): Construction of a substation and a 60MW farm was underway by 2019 H2.

- Stage 2(Demonstration): Construct a farm with a capacity of 400MW(inclusive of 60MW from stage 1)

- Stage 3(Expansion): The farm will be expanded to have a total capacity of 2GW(inclusive of 400MW from stage 2)

A pilot floating offshore wind power is in currently in the developmental stages. A pilot mid-depth floating offshore wind farm(750kw-class), the first floating offshore wind farm in Korea, is awaiting installation; however, connection to the grid is yet to be decided.

■Source. KISTEP, an excerpt from ‘Floating Offshore Wind Power Technology Demonstration Project.’