Special Report Digital Twin Technology Applications for Shipbuilding Equipment-manufa…

페이지 정보

작성자 최고관리자 댓글 0건 조회 417,755회 작성일 19-09-16 18:32본문

Introduction

Digital Twin refers to a technology which digitally replicates movements of physical objects. Various real-time operating data can be input to simulate outcomes necessary to predict the future. Recently, advances in technologies from the Fourth Industrial Revolution such as Big Data and Internet of Things(IoT) have put Digital Twin in the spotlight.

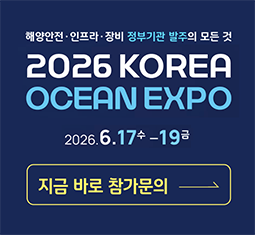

Digital Twin Ships utilise this technology to create digital replications of actual ships under the same conditions. Upon inputting real-time navigation data, actual navigation conditions can be digitally simulated. By running a range of test simulations, ideal, real-time navigation conditions can be identified.

Digital Twin Overview

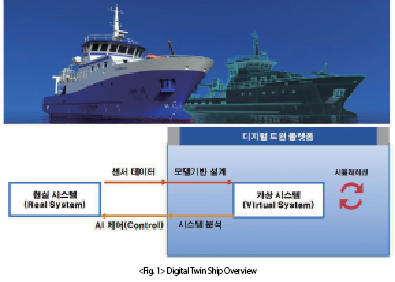

Technological advances in the Fourth Industrial Revolution such as IoT, Big Data, Artificial Intelligence(AI), and Cyber-Physical Systems(CPS) are being made and becoming growingly universal. Technologies are applied to improve productivity, economic efficiency and safety in various industries. To meet the growing demand for these technologies, Digital Twin is receiving much attention.

In summary, Digital Twin is a virtual clone of physical objects (assets, process, and systems) whilst maintaining the attributes of the target object’s environment throughout its life-cycle. It also meticulously models the movements of the primary object.

Ultimately, Digital Twin is a concept much like CPS. It is a cyber system like computing devices that simulate real-world people, operating environments, and machine equipment. It integrates physical systems into a network built on systems which can be reliably and autonomously controlled. In particular, this technology is necessary for large-scale systems(System of Systems) including smart cities, defence, transportation, smart grids, and smart production systems, in which many singular systems can be linked through a single network.

Autonomous Ships and Digital Twins

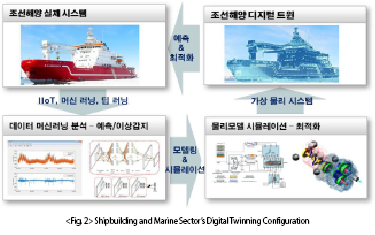

In recent years, intelligent autonomous vessels and related technologies have become a major global issue. Autonomous vessels self- or remote- diagnose and/or maintain to provide services in connection with value chains from industries such as ICT, shipbuilding and shipping to offer futuristic ships that are safe and energy-efficient. To realise autonomous vessels, it is necessary to develop domestic and international legal and institutional regulations and protocols, international standards, marine communication infrastructure, autonomous vessel service platforms, shipbuilding equipment and materials based on a synergy between advanced ICT and shipbuilding technologies. This amalgam of various technologies is required to increase safety, reliability and efficiency. Core technologies necessary for the realisation of autonomous vessels should be developed whilst considering the vessel's size characteristics. This is because small- to medium-sized vessels vary in speed capabilities, operating distances, type and quantity of equipment depending on its intended purpose and operational environment.

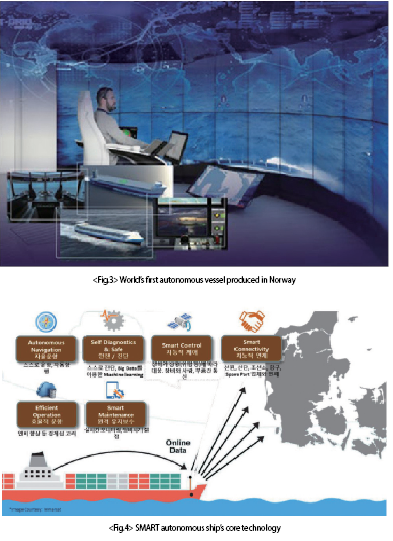

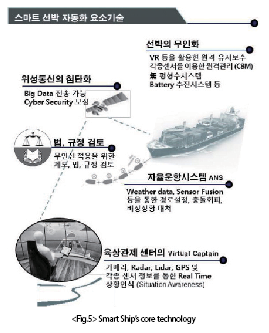

Core technologies necessary for the realisation of autonomous vessels can be differentiated into six categories: communications infrastructure, self-diagnosis, Digital Twin, environmentally friendly, and autonomous safety. Essential equipment for autonomous operation should be installed, and on-land services for autonomous navigational support should be provided. In addition, real-time data exchange and management should be built upon broadband communication networks and service platforms.

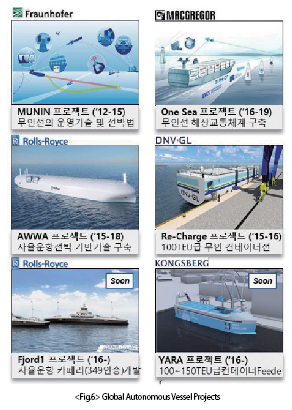

A prime example for mid- to large-sized autonomous vessel-related research is the Maritime Unmanned Navigation through Intelligence in Networks(MUNIN) Project. This project developed, based on simulations, and verified the concept of unmanned merchant ships(MUNIN, 2016). In addition, was the Advanced Autonomous Waterborne Application(AAWA) Project, which aimed at developing automated and remotely operational technologies for a variety of activities such as navigation and shipping(Rolls-Royce, 2016). In Japan, the Smart Ship Application Platform(SSAP) Project developed a marine data platform to respond to autonomous shipping technology. It has mounted related systems on two vessels and is carrying out data accumulation and analytical research(JSMEA, 2017). In Korea, the need for the development of mid- and large-sized autonomous shipping technology has been recently recognised instigating strengthened support for R&D of related technologies. The Research Institute of Medium & Small Shipbuilding has begun R&D on remote maintenance and failure prediction technology and incorporates autopilot and collision avoidance technologies.

There is much research related to small autonomous vessels, as it is less constrained relative to it's mid- to large-sized counterparts, making it easier to access R&D technology. In particular, development is active in the United States, Europe, Russia and Israel, giving them a technological advantage in small autonomous shipping technology. In Korea, related small autonomous vessel technologies are being developed solely for defence and exploration purposes, which are dangerous and have limited human access.

To advocate autonomous navigation, it is necessary to address technical, regulatory and market issues and a lack of intelligent software companies specialising in shipbuilding. Korea’s level of software technology is less than that of developed countries. Korea’s shipbuilding industry, which is experiencing difficulties, urgently needs to secure competitiveness through new AI navigation technology. The domestic navigation system market is expected to grow at an annual average growth rate of 12.3% from KRW 138 billion in 2015 to KRW 225.35 billion by 2021. Furthermore, the global navigation system market is expected to grow at an annual average growth rate of 4.4% from $3.5 billion in 2015 to $4.5 billion in 2021.

Autonomous Ship’s core technology

Autonomous ships operate by processing learnt information from the ship, sea, weather, navigated regions and past navigational data to understand the ship’s navigational conditions and prepare for unforeseen situations. In order for self-navigating ships to operate safely, it is necessary to possess autonomous navigational control systems for real-time autonomous navigation and control. Therefore, the following core technologies are required:

- Learning-based semantic navigation and knowledge-based technology which continuously collects changes in the ship’s internal and external conditions and understands data through integrated analysis to recognise the ship and its surroundings.

- Dynamic vessel operation control and route planning technology that determines the vessel’s route prior to departure and also operates flexibly according to changes in navigational conditions.

- Secured shore-to-ship control middleware technology which monitors the ship’s navigational status in real-time from on-land and can control the ship remotely, if necessary.

- Autonomous ship evaluation and modelling technology that adjusts according to the ship’s characteristics and information on the ship’s route prior to operation through simulated navigational performance modelling.

Expected Effects of Autonomous Ships and Digital Twin

First, autonomous ships will be connected to stakeholders to provide information and services. In self- and/or remotely diagnosing and managing the vessel to provide safe autonomous navigation, energy efficiency will be optimised. From vessel construction to operation, a new paradigm for operation will emerge and the autonomous ship sector will probably become a key determinant in the shipbuilding industry. Through fierce competition to secure innovative, autonomous vessel software technology, companies in this high-risk space will revive the stagnant shipbuilding industry.

Second, a simple manufacturing-oriented market structure, focused on shipbuilding and equipment sales, will be transformed into a value-added market structure which can continuously create new added value by utilising collected shipping, oceanic and weather-related data. Third, a drastic decrease in accidents caused by human error, which accounts for more the 85% of shipping accidents, can mitigate concern for marine accidents.

Automation of not only the ship’s design, construction and operation but also the ports and distribution chain’s will catalyse a revolution of all shipping-related infrastructure towards the Fourth Industrial Revolution(a Blue Ocean). Changes in shipping-related infrastructure built on autonomous vessels will be a ‘game-changer’ for the industry and help give rise to a new market worth approximately $8 trillion. If final ‘shipping’ consumption were to reach a unit value of KRW 1 billion, then this would directly and/or indirectly add 0.581 units to the national economy. In addition, is also expected to lead to an extra 8.2 units of employment from the new market’s contributions, especially in areas related to the ship’s operational system and other relevant functions such as testing, navigation, control and precision instrument manufacturing sectors. Inevitably, this will lead to a 6.77% rise in profits.

In addition, control of the ship is possible from a landed facility. The autonomous ship’s artificial intelligence system for navigation control will safely and reliably collect and analyse the ship’s data through the use of a Smart Ship information security service platform. On land, the condition of equipment installed onto ships can be effectively understood, also various professionals will have access to shared real-time information to allow for collaboration to restore errors. This will reduce navigator workloads and improve working conditions by enabling collaborative work for a remote maintenance service platform. The technology can be established as a land bridge for remote monitoring and control for ‘watch-free’ bridges and unmanned ships. Therefore, ship navigation-related data can be accumulated from knowledge and experience to be useful for designing future vessels such as unmanned vessels, energy-saving vessels, eco-friendly vessels, and/or vessels optimised for the needs of its owners.

The following summaries the core abilities that make Digital Twin use for autonomous vessels possible. Professional data capabilities within the autonomous navigation industry, which supports the smooth flow(usage) of data to provide an overall view of an asset throughout its product life-cycle. And an ergonomic physics model and(3D) digital model deduction capabilities, big data analysis, knowledge extraction capabilities and analysis suitable for industrial application, and/or the ability to develop application software capable of predictions.

Hydrogen Ship and Digital Twin

Last January, the government announced plans to position Korea as a leader in the hydrogen economy by announcing a roadmap to revitalise the hydrogen economy. The roadmap provides directions for diagnosing the overall hydrogen industry at home and abroad to become the world leader. This roadmap, which is linked to the government’s ‘Roadmap for Revitalising the Hydrogen Economy’, was established with the goal of promoting hydrogen ships as a ‘promising future item’ of the shipbuilding industry by diverging its strategy into costal and ocean-use ships. With coastal-use ships, the fuel cell system is to be verified by 2022, and commercialisation through experimental ships is to be carried out by 2025. For ocean-use ships, research and infrastructure development is to be carried out simultaneously in-time for application on ships by 2030. Amidst developments, the Korea Society of Shipping and Shipbuilding(KR) is working with industry, academia and institutes to establish a hydrogen technology roadmap. Future policy will actively advocate hydrogen fuel cell-propelled ships hydrogen storage and hydrogen tankers and other R&D. Since 2010, KR has analysed hydrogen fuel cells and hybrid systems as a power source for ‘next-generation ships’ and has since carried out many R&D projects to apply relevant technology to ships. KR has acquired outlines, safety standards and approval regulations like those of "Liquid Hydrogen Transportation Cargo Containment System(CCS) Design and Verified Technological Development” and "Non-polluting Ship-use Proton-Exchange Membrane Fuel Cell(PEMFC) Hybrid System Development”. Besides KR’s R&D, they are also planning to prepare reliable stage-by-stage technological development safety standards for the commercialisation of hydrogen ships. KR plans to apply several hundred kW class fuel cell system immediately after safety inspection and approval by 2022 and establish a foundation for hydrogen transportation and MW class marine fuel cell system by 2025.

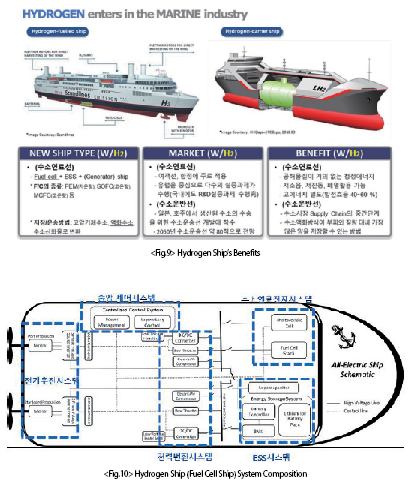

Hydrogen Ship Benefits

Hydrogen ships are driven by electric fuel cells. Three parts make up the fuel cell’s power system: hydrogen(or hydrocarbons such as natural gas), fuel cells that generate electricity, and electric motors that generate propulsion. There are no commercial fuel cell vessels yet. Therefore, fuel cell ships are not fully conceptualised. However, fuel cells are being tested in a variety of vehicles, trains and aircraft, so it can be presumed that fuel cell ships will be developed. Aside from the power system, Fuel Cell Ships(FCS) are not much different from ordinary ships. However, as power systems are an integral part, their fluctuation will have a significant impact on the ship’s structure and operation.

Expected benefits of a hydrogen ship are listed below:

(1) High thermal efficiency reduces ship fuel costs. Considering the gravity of a day’s worth of fuel costs for large bulk carriers, oil tankers and container ships are significant, the thermal efficiency of a ship’s power system is beneficial for transporters and cargo owners. This is also beneficial to a country’s economy.

(2) Environmentally friendly. Large vessels consume large amounts of fuel, leading to high emissions. Diesel ships emit not only carbon dioxide but also nitrates, sulphur compounds and soot. However, fuel cell ships have little to none pollutants. In addition, as electric motors drive Fuel Cell Ships, there is no noise pollution or vibrations associated with large diesel engines. Thus, Fuel Cell Ships would be well-suited for ferries and luxury passenger ships.

(3) Mitigates contributions to global warming and is adaptive to expected environmental regulations. Regulations on emissions are being tightened around the world. However, the environmental friendliness of Fuel Cell Ships deviates from these regulations. Ship emissions receive less attention because they not near residential areas. However, the ever-increasing volume of ship traffic and growing environmental concerns, environmental regulations for ships will become stronger. Thus, Fuel Cell Ships are a realistic alternative to these regulations.

(4) Large vessels do not require auxiliary generators, and ship design is more flexible. Existing ships install auxiliary diesel engines for power generation. However, this is not required on a Fuel Cell Ship as it produces its own energy, which helps to cut costs. When producing energy, one big engine is more efficient than two diesel engines. Also, one engine is more cost-efficient when compared with the cost of producing another engine and fuel consumption. In contrast, having one big motor is not necessarily better than having several motors. With special vessels, the motor can be installed either in front of or on the side of the ship to increase agility during navigation and operation. Diesel engines are more difficult to install and replace. For Fuel Cell Ships, aside from the motor, as power components comprise modules, parts can be replaced easily.

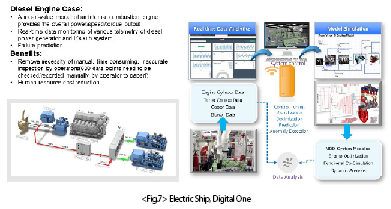

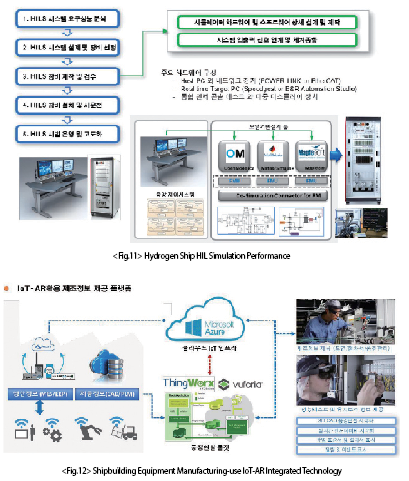

Hardware in the Loop(HIL) Simulation for Hydrogen Ship Modelling

The components of Digital Twin digitally embody the complexity of the hydrogen ship’s fuel cell system, electrical storage system, and thrust system. In particular, software capable of interpreting and optimising the system is essential. Digital Twinning needs to be operated based on precise modelling. It is to optimise various elements of the system and also to transcribe the real system onto a virtual platform to perform various simulations. Precise simulations need to be made possible to get valid results. Depending on the situation, a model incorporating physicochemical analysis should be undertaken to refine the data further.

Digital Twin also uses various sensors to detect changes in the physical world’s environment. The virtual world recognises, analyses and predicts the physical world based on information collected from sensors and advanced system models which reproduce and project the physical world. The results are then inputted into the physical system to make adjustments accordingly. This changes the state of the physical system and forms a cycle in which information is recollected.

Through virtual simulations by HIL, improvements can be made to a hydrogen ship’s core equipment development process. The combination of tools provided by Model-Based Design(MBD) with HIL can drastically greater the process’s effects. MBD tools can also help to enhance the physical model, and by combining the modified model with optimisation algorithms, calculations can be carried out to higher efficiency. In addition, calculations can be applied in lieu of parameter values and model calibrations to obtain arbitrary and dynamic characteristics.

Recently, Cyber-Physical Systems(CPS) and Digital Twin, which goes beyond traditional embedded systems, have been attracting attention as a new paradigm. Unlike traditional systems that operate individually, Digital Twin emphasises close interaction between computing systems and the physical world. In particular, Digital Twin utilises telecommunications technology to observe, calculate, and manipulate established relationships between individual systems. Ultimately, communication, computation, and control are designated as the core concepts by which humans coexist with the cyber world through physical entities such as sensors, actuators and embedded systems. These allow for even more accurate system optimisation and operational forecasting.

The convergence of the Internet of Things(IoT) and Augmented Realit (AR) technology in Shipbuilding and Offshore Plants

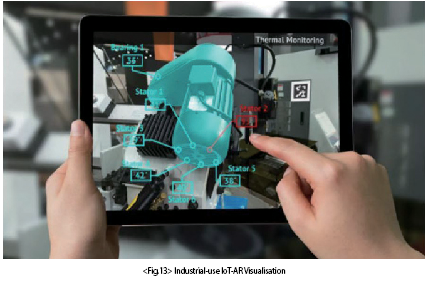

The shipbuilding and offshore plants industry is developing safety content for crane signal reception, yard crane workers, and sailors and passengers. In particular, this development provides safety information services for crane signal control to improve worker safety by preventing accidents, collision prevention, and safety distance control. Create several virtual safety training cases, by type of hazard, to recreate actual situations, ultimately to mitigate unnecessary hazards. Virtual experience programs for safe navigation is also expected considering the ever-growing number of cruise passengers and fishing vessels. Upon developing content, it first is used in the shipbuilding industry, and then will further expand into the manufacturing and construction industries. It is expected to enhance timely, spatial and economic effects through augmented virtual reality safety information services and education programs which closely mimic real-life situations, especially for industries with high workplace fatalities such as shipbuilding and ship operations.

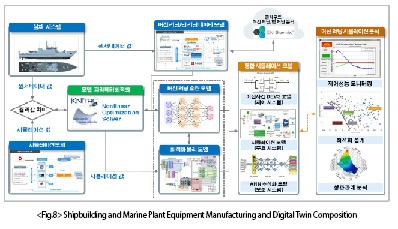

<Purpose and applicable sectors>

Unlike general production lines, shipbuilding equipment manufacturing production lines are not centred around equipment, but a work-oriented process in which workers check the product’s drawing, work standard and quality control information. Over the past few years, recession in the shipbuilding and offshore plant industries has dissuaded many skilled workers. In order to re-secure highly skilled workers, ample time and money have to be invested. Recently, AR technology has a tool to guide work and the manufacturing process. Its synergy with IoT is favoured by global manufacturers for its ability to digitise the process by fusing data information transmission and functionality analysis. The economy is also reviving LNG carriers; however, still requires improved productivity of workers and the shipbuilding industry. It is essential to develop a manufacturing information supply system for shipbuilding equipment factories using industrial AR-IoT technology.

Easily call and read a digital manual in front of one’s eyes. One can also watch educational videos or call a professional directly by voice. One’s visual movements can be streamed in real-time to a professional. The professional can then give instructions as if they were on-site. According to one study, even when working with smart glasses for the first time, productivity improved by 34% compared to standard working methods.

Conclusion

Design and work information(CAD/PLM data, work standards, etc.) for shipbuilding and offshore plant equipment companies have visualised through the use of AR. Visualisations have been customised to workers’ mobile device (smart glasses, tablets, etc.) displays to help workers understand the manufacturing process and to collect, convert and store real-time data such as wiring check and performance test information required for work to IoT Cloud infrastructure installed in the workplace which can store, analyse and inform results in real-time. The convergence of digital twin and IoT-AR technology is in line with core application areas for the shipbuilding and offshore plant industry. The presented information is based on a shipbuilding and marine plant industry-use digital twin and industrial-use IoT-AR technology project carried-out by JNE SYSTECH CO.