Issue Steelpaint to protect Emden Great Sea Lock

페이지 정보

작성자 최고관리자 댓글 0건 조회 2,095회 작성일 25-03-05 21:20본문

Steelpaint to protect Emden Great Sea Lock

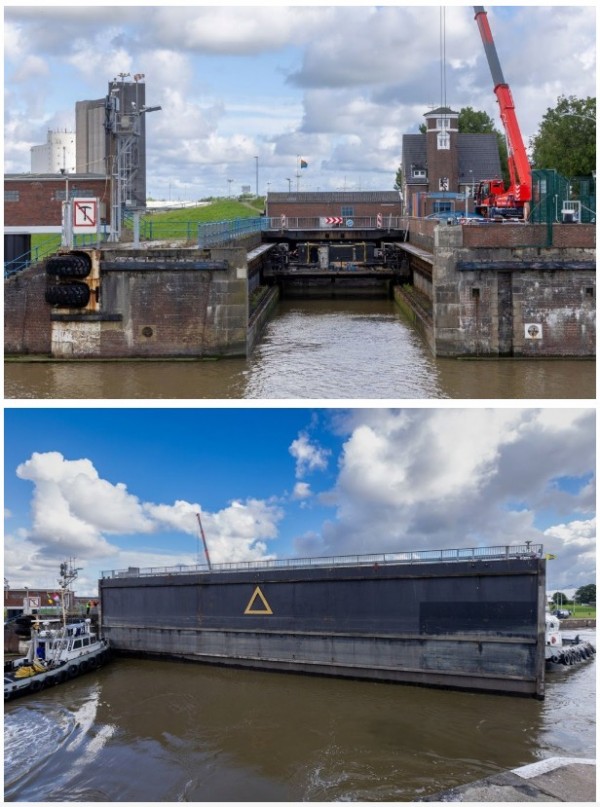

The historic Great Sea lock will be refurbished with a Steelpaint protective coating system. Photographs courtesy if Andreas Burmann/NPorts.

Emden’s Great Sea Lock (Große Seeschleuse) is to be protected from corrosion with a Steelpaint coating system following a substantial contract award by the Lower Saxony Port Authority (Niedersachsen Ports) as part of major refurbish and renewal project.

Opened in 1913 to provide a maritime gateway from the North Sea to the River Ems, the Great Sea Lock – one of the world’s largest – is being renovated and adapted to provide greater flood protection. As the lock will remain operational throughout the upgrade, the €100m project will take about ten years to complete.

The milestone project, implemented to facilitate the smooth operation of the sea lock for the next 35 years, will involve constructing new reinforcements to optimize flood defence, the construction of new transformer stations, a reserve gate and a cable pull system.

"We are privileged to have been selected by Niedersachsen Ports to play a key role in this landmark infrastructure project," said Frank Muller, Steelpaint’s Sales Director. "Our proven track record in delivering high-quality, durable protective coating solutions for maritime applications made us the ideal partner for this critical undertaking."

Steelpaint will supply a comprehensive coating system for approximately 50,000m2 surface area across the Emden lock's gates and associated structures. This includes a 75µm zinc-rich primer coat, forming a sacrificial barrier to shield the underlying steel from the harsh saltwater conditions.

On top of this, two to three coats of Steelpaint's proprietary Stelpant-PU-Combination 300 polyurethane coating will be applied with a 150 µm to 225µm dry film thickness. Some areas will also be coated with an additional UV-resistant semi-gloss topcoat of 80µm.

Steelpaint has a successful track record with several ports operated by NPorts, explained Fynn Baumfalk, Steelpaint’s Key Account Manager Protective Coatings. “Our coating systems have been trusted to protect hydraulic engineering buildings for decades, delivering exceptional results in a hugely challenging marine environment. Stelpant´s specialized formulation means this coating can withstand constant exposure to saltwater, UV radiation, and other weathering factors, providing long-term protection to Emden’s new lock gates."

Wilfried Schleusener, responsible for operating systems at Niedersachsen Ports Emden: "The Emden lock project is one of the largest hydraulic engineering initiatives currently underway in Germany. By elevating the lock gates and reinforcing the surrounding infrastructure, we can future-proof this vital infrastructure against the effects of climate change and rising sea levels. We are confident that Steelpaint’s innovative coatings will help keep the Emden lock operational for generations to come."

The lock gates themselves are massive structures: 42m wide, 20m high, with a 7m draught. Raising each 860t gate by 2m is a significant engineering challenge, but one that the Port Authority is committed to undertaking to enhance the historic lock's resilience and longevity.

The renovation work will be carried out in phases to minimize disruption to port and shipping operations. Steelpaint's coatings will be applied as the new gate structures are fabricated, with the first two lots already in the tender process.

"This contract represents a significant milestone for Steelpaint, solidifying our position as a leading supplier of protective coatings for major port infrastructure projects," said Baumfalk. "Our expertise in meeting the unique challenges of the marine environment, combined with our commitment to quality and customer service, were key factors in securing this prestigious project."

Beyond the Emden lock, Steelpaint is also in discussions with the Port Authority to provide protective coatings to the Cuxhaven container terminal, which is undergoing expansion to meet the requirements of the offshore wind energy industry. The Kitzingen-based coatings specialist is also involved in the refurbishment of the Hooksiel sluice gate in Wilhelmshaven.

■ Contact: Steelpaint GmbH www.steelpaint.de/en/