Special Report The future-proof ship

페이지 정보

작성자 최고관리자 댓글 0건 조회 3,291회 작성일 19-11-15 16:10본문

The IMO’s decarbonization targets force the shipping industry to prepare for entirely new energy sources. How future, low-carbon vessels will be powered has yet to be decided so new ships must be designed with flexibility in mind.

Since the introduction of the first diesel-powered ships in the early 20th century, technology developments in shipping have been steady and incremental. This continuity will end as the industry approaches the year 2050. Decarbonization requirements and the opportunities offered by digitalization will bring about major change. The challenge for a ship built today is that this change will take place within its lifespan. Failure to account for foreseeable regulatory and technology developments may render a ship built today uncompetitive at best; in the worst case it may end up being prohibited from operating altogether. The technology choices made when building a new ship will therefore decide whether it will be future-proof.

Ambitious emission targets

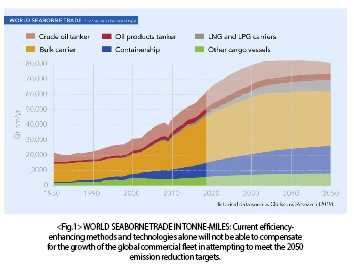

In 2018 the IMO adopted a climate change strategy that calls for greenhouse gas (GHG) emissions to be reduced by 50 per cent by 2050 compared to 2008. The total reduction required per ship will depend on the development of the global fleet. The Maritime Forecast to 2050, a part of DNV GL’s Energy Transition Outlook, estimates that seaborne trade will grow by approximately 40 per cent between 2008 and 2050. To reach the 2050 GHG emission target, the emissions from any ship will have to be less than 30 per cent of an average ship’s emissions today. The target also implies that ships built in 2050 must emit considerably less than that to offset older ships with higher emissions that are still in operation. All this means that enormous emission reductions must be achieved very soon for the target to be within reach.

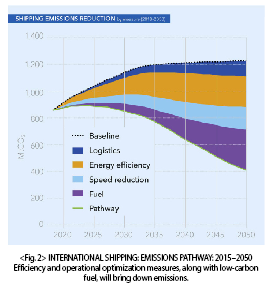

There are essentially two areas that must be addressed to meet the reduction goal: minimize the energy required to operate the ship, and reduce the carbon emissions from energy generation.

Addressing energy use

The energy requirement can be lowered to some extent by implementing operational measures, such as reducing speed or optimizing routes and logistics. Furthermore, ship design can be improved in various ways, from choosing the most efficient ship size to using alternative materials or technologies, such as hydrodynamic optimization of the ship hull and air lubrication. Additional technologies can be employed to generate the required energy more efficiently. Examples include waste heat recovery from energy conversion, hybrid energy systems, and devices enhancing propulsion efficiency.

However, efficiency enhancements alone cannot nearly achieve the emission reduction required to meet the 2050 goal. In fact, the DNV GL Maritime Forecast to 2050 concludes, these measures will not even fully compensate for the increase in emissions caused by the expected growth of the global commercial fleet. The industry must therefore prepare for the future use of low-carbon energy carriers while using fuels with reduced carbon intensity and low nitrogen oxide (NOX) emissions, such as LNG and LPG, for a transitional period until there is sufficient clarity regarding the way forward.

Commercial barriers and scaling of technologies

Batteries can be used as a carbon-free energy source in some coastal, short-distance applications and as energy buffers for on-board electricity needs to reduce dependency on auxiliary engines. The amount of energy required for long-distance shipping, however, must be carried on board in fuel form. Nuclear energy has been discussed as an emission free power source but is unlikely to find public acceptance following the Chernobyl and Fukushima disasters.

Biofuels may play a role but with the world population growing, the available agricultural area will most likely be needed to grow food for human consumption. Carbon capture-and-storage, practiced to some extent already, is favoured by the fossil fuel industry because it will allow the continued use of mineral oil and gas. However, doubts remain regarding the long-term tectonic stability of geological formations used to store CO2.

Future carbon-free energy carriers will therefore most likely be synthetic fuels generated from renewable energy. The current discussion focuses on hydrogen produced by electrolysis using wind or photovoltaic energy. To avoid the technical challenges associated with long-distance transport of hydrogen, conversion to ammonia, methane or methanol is being discussed. Methane could be distributed using existing natural gas and LNG infrastructure.

Perhaps the most critical obstacle currently standing in the way of implementation at scale is commercial viability. All zero or low-carbon energy carriers mentioned come with severe financial penalties in the form of high capital expenditures required to equip ships to use these fuels and the cost of the energy carriers themselves, which translate to high operating expenses.

One of the reasons for the high costs is the current inavailability of both, the technologies and the energy carriers, at sufficient scale. Great efforts must be made to overcome these hurdles and reduce the costs to a level that makes at least some of these solutions financially attractive. However, since the cost gap between these and current solutions is very wide, it will be a long time before the shipping market will be able to scale any of the alternative solutions to the required level.

The only hope to reach the IMO’s GHG reduction target by 2050 is timely implementation of global regulations that will drive the development of fuels and technologies. There are basically two options which are not mutually exclusive: Implementation of technical and operational requirements, such as the current Energy Efficiency Design Index, and/or a ban on carrying and using energy carriers exceeding a specified carbon content, similar to the 2020 “sulphur cap”; and/or implementing market-based measures, such as a CO2 tax, which essentially puts a price tag on CO2 or all GHG emissions.

Given today’s cost of zero-emission solutions, for a tax mechanism to work the cost per tonne of CO2 equivalent may have to be in the order of several hundred US dollars, for some solutions even in excess of 1,000 US dollars. If a solution is scaled successfully, this tax may be reduced over time. However, should any such tax or ban be implemented on existing fuels, the consequences could be devastating for shipowners who have failed to prepare for such an eventuality. In the best of cases the result will be massive additional costs for retrofitting and/or higher fuel prices; in the worst case, ships will become inoperable well before the end of their life cycle.

An alternative scenario would be to use an emission tax to establish a fund to finance the development of new solutions. Such a tax would not have to be as high; its purpose would not be to force operators to adopt a new solution, but rather to enable innovators and first-movers to develop, test and scale cost-effective, low-carbon emission technology.

There are exceptions to this scenario for technologies and energy carriers adopted in some short-sea shipping applications and geographies, but these segments account for a very small portion of emissions from global shipping.

Digitalization: the second game changer

The other disruptive force is digitalization, which has already transformed many aspects of society, including some aspects of the shipping industry as well. The power of digitalization lies in its information processing power. The resulting insights can support better decisions and make the operation and management of ships more cost-effective and competitive. The distribution of costs associated with operating and managing a ship depends on the ship type and operational profile, but the main cost items are administration and crew, repairs and maintenance, and of course fuel.

Some ship operators are taking advantage of IT-enabled efficiency enhancements by centralizing information-processing and decision-making at shore-based operation centres. This requires significant transmission bandwidth between the ship and other relevant information sources, and the operation centre.

If sufficient information is provided and processed in a timely manner it may even be possible to make real-time operational decisions at the on-shore operations centre. This would allow shore-based staff to control certain functions remotely so that the physical location of some operational personnel could be shifted to shore. Eventually computers might be able to make reliable decisions regarding specific functions independently based on digital information, which would reduce the need for personnel, whether on board or at the shore. Optimizing decision processes based on digital technology consequently harbours significant potential for cost savings.

Repair and maintenance costs are related to the type and robustness of the equipment to be maintained. Equipment condition monitoring has the potential to dramatically reduce these costs by enabling maintenance to be carried out precisely if and when required, avoiding the need for unscheduled repairs. While condition monitoring is possible without digitalization, the complexity of carrying out the required diagnostics and prognostics in a timely manner renders such an approach impractical for most types of equipment. Digitalization is therefore an enabler of cost-effective condition monitoring.

A key factor in this scenario is the need for deep insight into the function and failure modes of the equipment being monitored. For complex equipment, only the designer and manufacturer may have this insight. However, the ability to transmit digital condition information to shore enables manufacturers to take the responsibility for condition monitoring and maintenance, relieving the ship operator of this duty. In the aviation industry this shift of the responsibility for monitoring, and to some degree, maintaining and repairing the equipment to original equipment manufacturers(OEMs) has occurred already. It is usually linked to novel business models such as ‘power-by-the-hour’ contracts. An important observation in this respect is the simultaneous shift in incentives; it is in the OEM’s interest to make its equipment as reliable as possible and to maintain it as cost-efficiently as possible.

Great challenges and opportunities for digitalization

Of course, digitalization has an impact on decarbonization as well and can support efforts to reduce energy consumption. For example, software algorithms can not only help optimize the operation of the ship itself but also improve its utilization by managing the entire logistics chain. Smaller crews could free up space for carrying more cargo and reduce the need for auxiliary power, thereby lowering fuel consumption.

Wherever digitalization is used to make shipping more efficient and cost-effective, digital information is required as input. This information is provided by sensors and other digital sources and must be processed by computers using algorithms. It is essential that all input data is of high quality and can easily be shared between different stakeholders and systems. A future-proof data infrastructure will be based on standards rather than proprietary solutions so as to enable transparency and openness.

Decarbonization and digitalization present the maritime industry with both, great challenges and great opportunities. DNV GL is investing significant resources to gain insight into how the maritime industry may develop in terms of decarbonization and digitalization, and to support its customers in this process.

■ Source: www.dnvgl.com